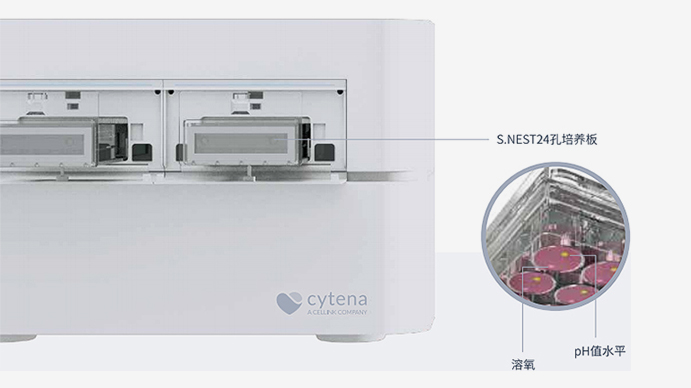

With the development of the biopharmaceutical industry, many companies are seeking competitive advantages in cell line development. S. NEST is a high-throughput micro bioreactor with CO2 incubator function, which shortens the process time of cell amplification, provides a better microenvironment for cell growth, and brings higher efficiency to cell line selection.

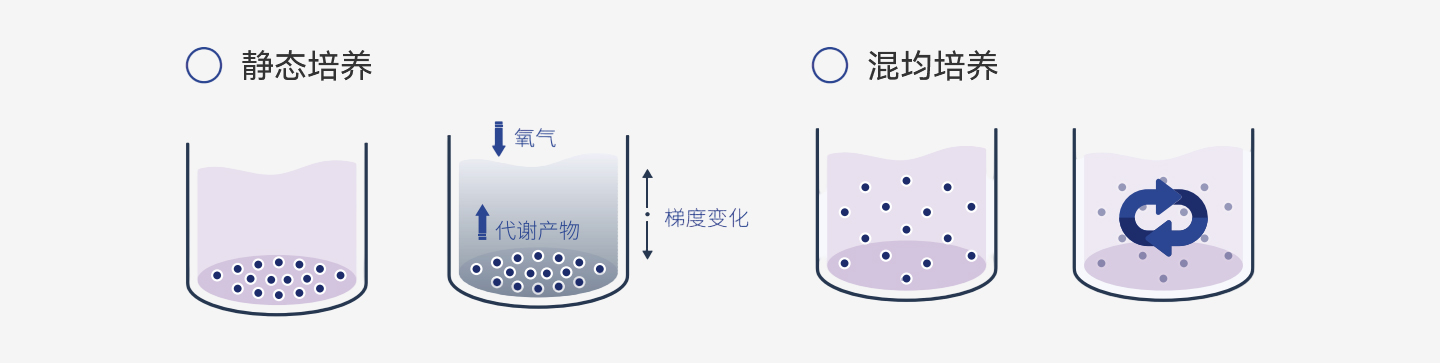

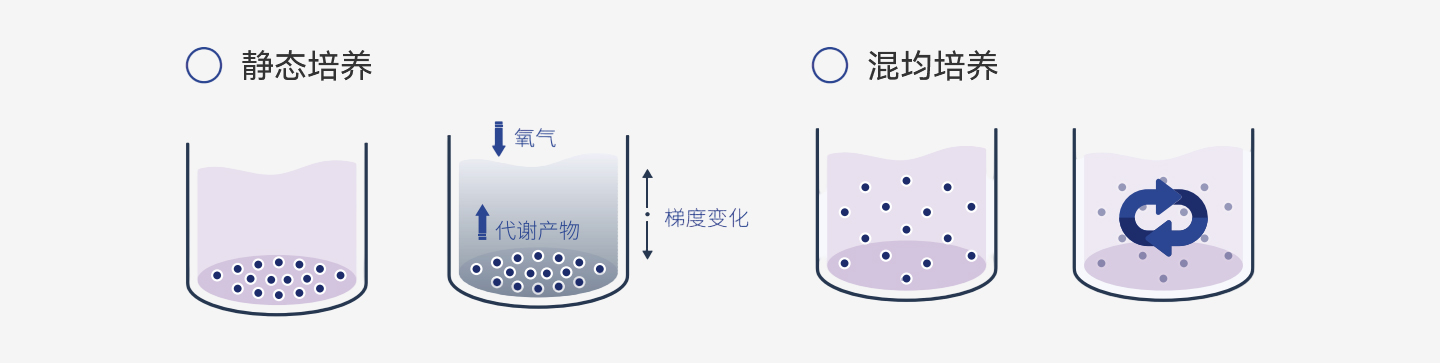

S. NEST introduces suspension culture and post bioreactor conditions into the early cell line development process, providing cells with more growth space and oxygen compared to static culture. When using S During NEST, compared to conventional culture methods, cells exhibit higher density and vitality, and no longer require several weeks of cell expansion time.

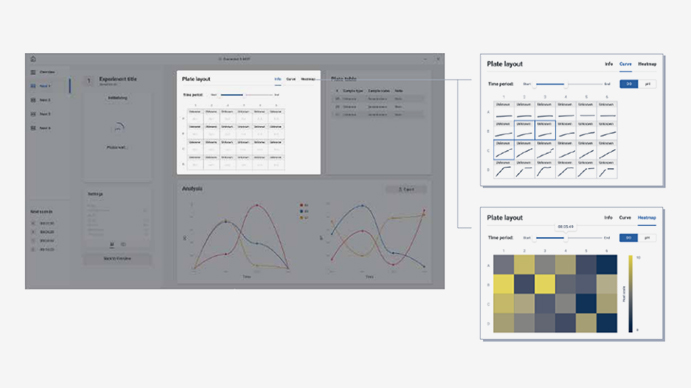

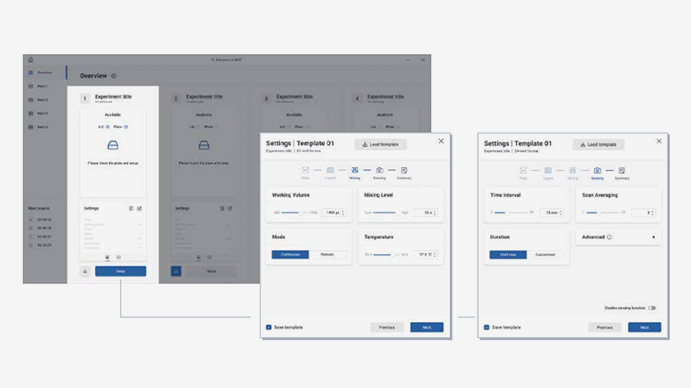

S. The NEST software displays the sensor's result data and allows users to adjust their control over the environment. Optical sensors are installed at the bottom of each hole to simultaneously monitor the pH and DO values of all holes.

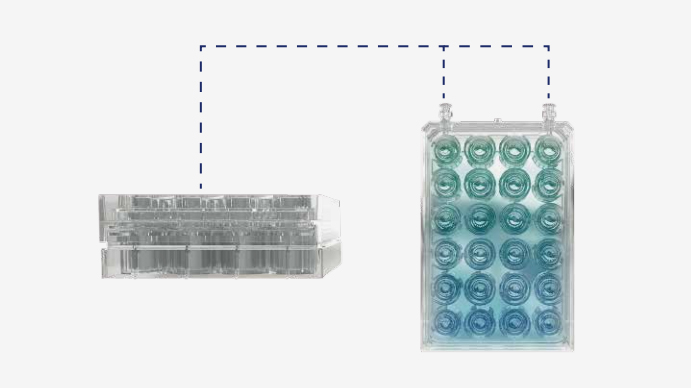

S. The NEST lid comes in two sizes: 96 fluid channel or 24 fluid channel, which can be used for corresponding culture plates. The patented condenser design in the fluid channel can effectively reduce liquid evaporation. During each mixing process, the condensate collected on the surface of the condenser is circulated back into the culture.

S. NEST can apply suction or discharge pressure through fluid channels to achieve uniform reciprocating mixing. For different cell lines, mixed control can be adjusted to minimize shear force

The oxygen delivery tube connected to the lid provides continuous oxygen supply to cells to maintain a healthy environment.

- Heat map of each well on the culture plate from start to finish

- Measure each hole at a fixed time interval

- Time curve table of selected hole data

- Cultivation room environment (temperature, CO2 level, and humidity level)

- Mixing system (mixing level and mode)

- Dynamic camera (time interval and scan average)